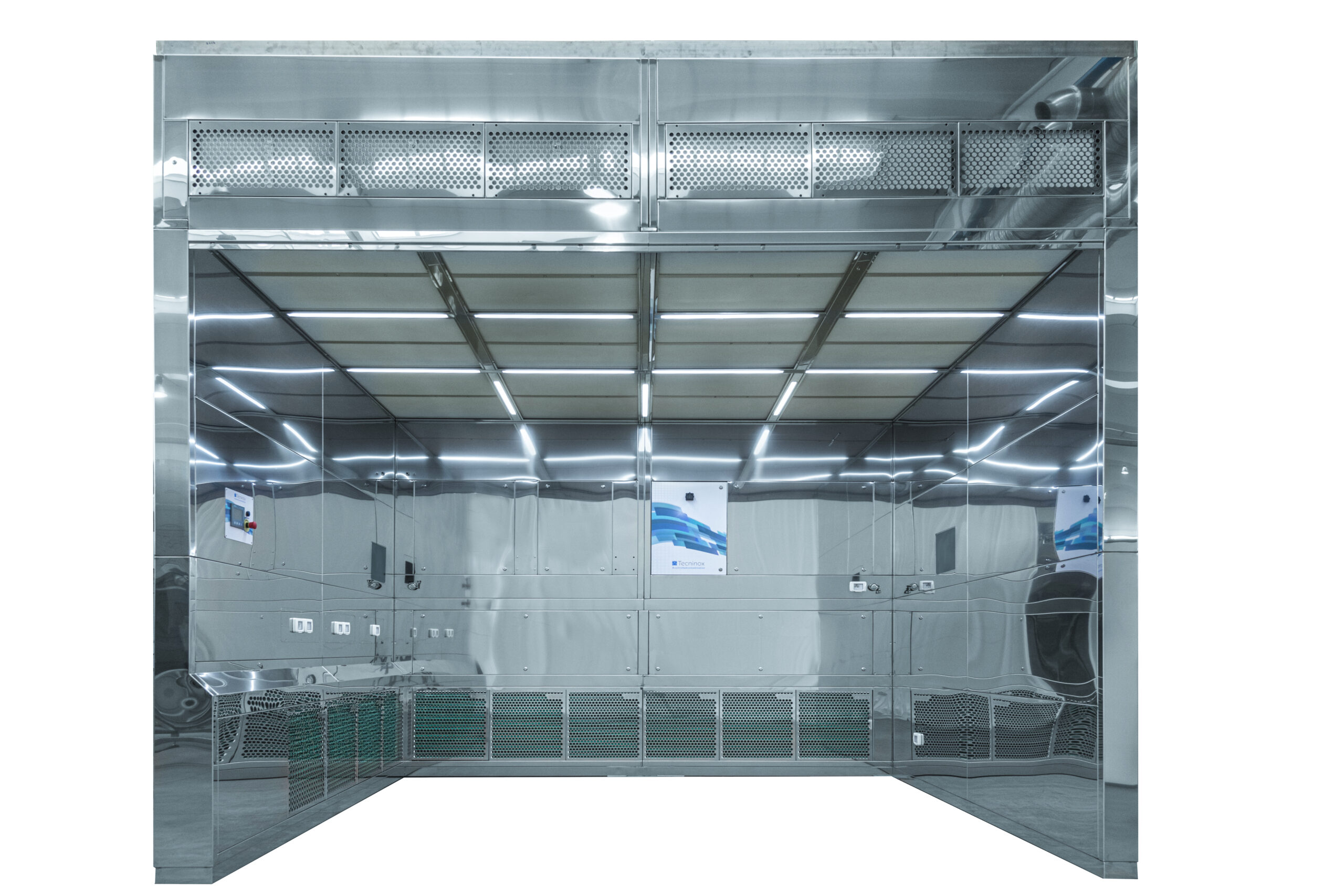

KAPPA – VERTICAL DOWNFLOW HOOD

This vertical laminar flow hood is ideal for the processing of powders and other substances…

INVISIBLE BARRIER

Invisible Barrier An invisible air curtain to protect the operator, the product and the environment…

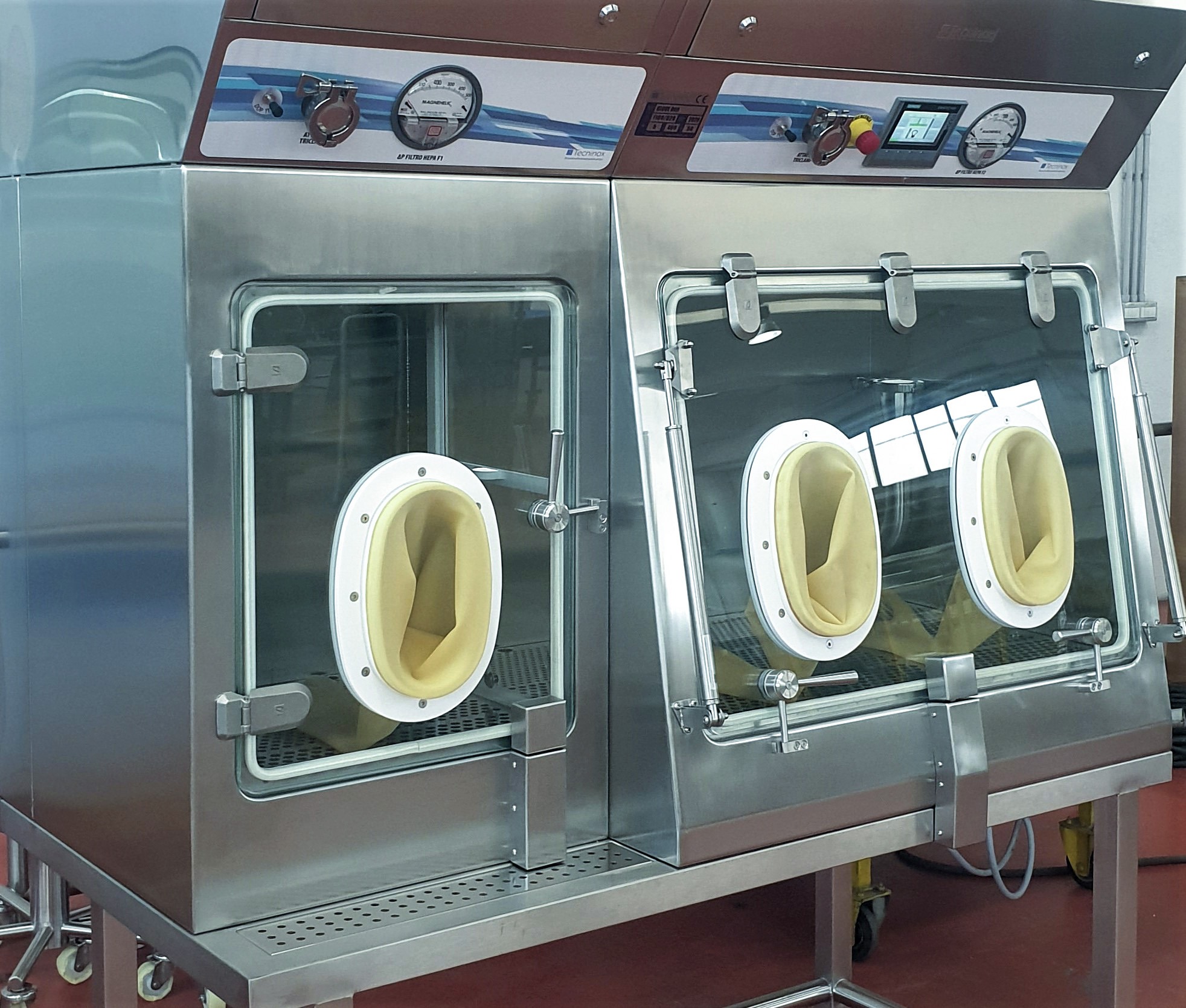

ISOTEC – INSULATOR

The insulator system allows for the manipulation of products and the performance of activities in a …

KAPPA – POWDER CONTAINMENT HOOD

This vertical laminar flow hood is ideal for the processing of powders and other volatile substances, which are constantly spreading inside the working area during the weighing, dosing or sampling of chemical and pharmaceutical substances. Kappa is available in a wide range of standard dimensions that can meet most of the requests. Alternatively, it is possible to develop customized solutions according to specific requests from the client.

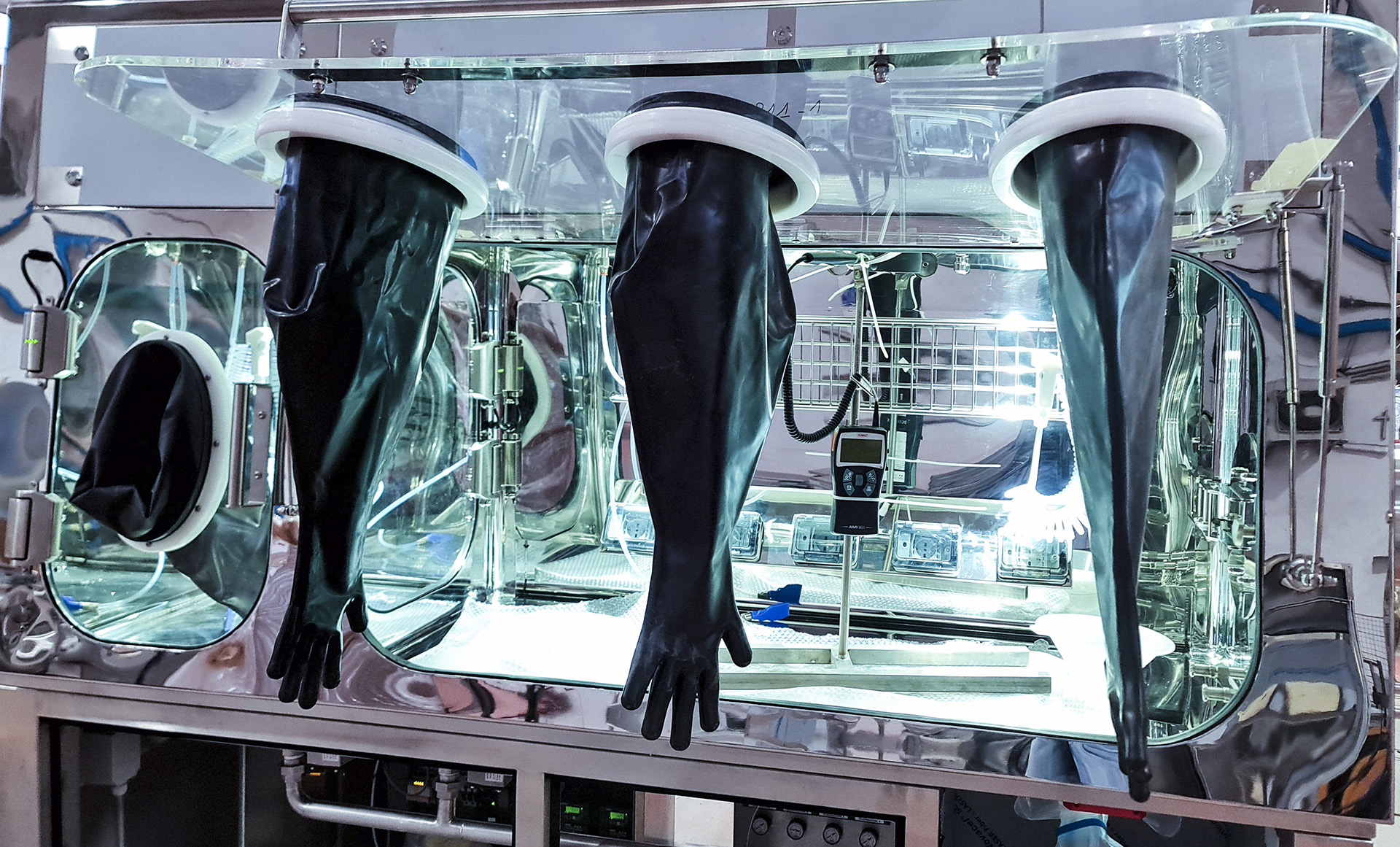

INVISIBLE BARRIER

Invisible Barrier An invisible air curtain to protect the operator, the product and the environment. It is suitable for multiple production processes such as weighing, sampling and filling, and for a number of sectors: not only the pharmaceutical one, but also the cosmetics, chemical and lab and for any processes requiring to be performed in containment conditions. It is available in open or closed, single or combined versions, equipped depending on the type of application required and in ATEX execution. Invisible Barrier, developed according to the latest GMP, can be customized to meet the specific needs of each client and enables to reach a level of containment up to OEB 4 (in models with front screen and gloves) and a cleaning class 5 of the working area ( per ISO EN 14644-1).

ISOTEC – INSULATOR

The insulator system allows for the manipulation of products and the performance of activities being completely isolated from the department or cleanroom in which it stands. ISOTEC systems allow to maintain the cleaning requirements, and, if requested, of sterility, inside the containment chambers while protecting the operator and the environment from highly toxic products. Tecninox develops designs and provides increasingly sophisticated insulating systems thanks to an ongoing collaboration with the hospital, pharmaceutical, chemical, cosmetics and food sectors. A special design guarantees total containment and safety in the processes involving API components, assuring positive results to every production run. Thanks to its wide range of possible configurations and options, ISOTEC laminar flow line covers all the needs both in positive pressure (human cells reproduction, aseptic operations, sterility tests, weighing, dosing, fractioning, packaging and transferring) and negative pressure applications (fractioning, weighing, milling, micro-milling and transferring).

Discover ours

#controlledcontamination

Our commitment to the future, which begins today, is the enhancement of all resources: people, territory, environment, with responsibility and innovation.

Our manifesto contains all the values underlying the change that will lead us to 2030 with a spirit of internal improvement and towards the world.